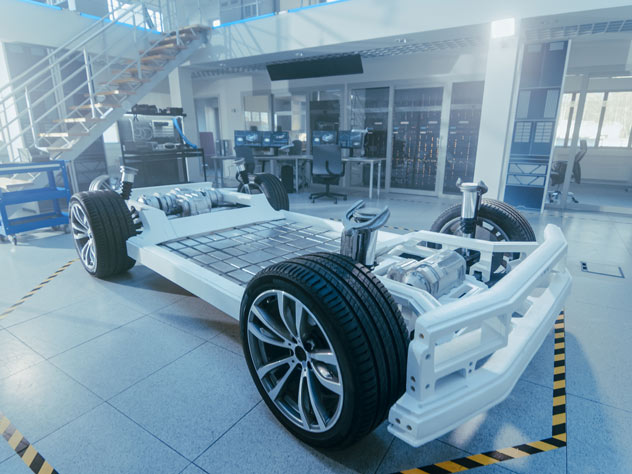

When we think about autonomous vehicles and their components, what really sets them apart is the sheer volume of items such as lidar and radar sensors, cameras and touch screens, and of course the computer that’s the brains of the car.

These components are high-value, fragile, sensitive and generally in a hurry to get to their destination, whether that be the OEM production plant or a customer who needs a replacement part.

This presents several logistical challenges, from security and traceability, speed to destination, and of course damage prevention amongst others. As the world leader in autonomous vehicle logistics Kuehne+Nagel is constantly innovating to meet these requirements. Our Airside solution reduces direct and indirect damages by cutting handling times and adding additional surveillance.

Specific services currently include:

- Fast track handling process to catch the next flight out

- Inspection along the way for critical shipments

- Special packaging such as va-Q-tainers to avoid any damage to components

- Forklift operation, stand activation and conversion, organization of equipment

- Checklist-based inspection in line with the criticality of your shipment

- Pictures of loading and unloading process

- Monitoring messages from the HyperCareTeam

- Handling supervision (in case of full freighters)

- Defect reports including pictures

- Early detection and rapid intervention to correct and mitigate if needed

We’re also not content to sit on our laurels and constantly strive to provide our customers with additional peace of mind. Soon smart labels will provide 24/7 visibility in real time along with the big data necessary to retroactively optimise supply chains. Recognising the critical knock-on impacts that problems in the supply chain can have on just in time production lines for example, consequential insurance provision will also be added to the solution in the future.

Talk to our autonomous vehicle logistics professionals to find out how we can help you.