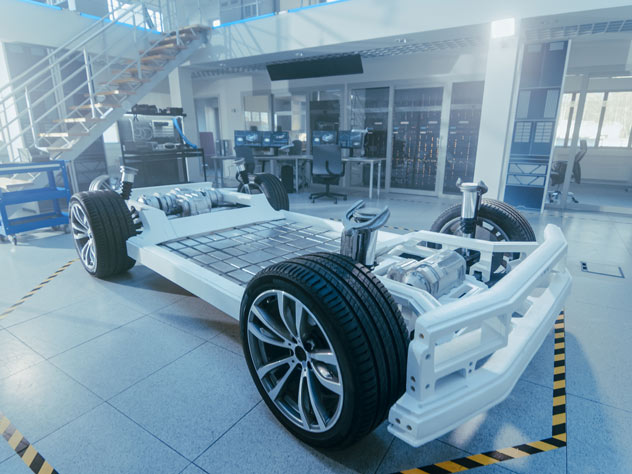

The specific characteristics of these new generation vehicles, notably significantly less parts than internal combustion engines, as well as their fragility and high value has required a profound re-design of associated supply chains.

Bespoke inbound logistics

In contrast to internal combustion engine (ICE) vehicles, BEV and HFC vehicles are essentially made to order, for individual customers. Their relative ease and speed of assembly (compared to ICE vehicles) means that just in time inbound logistics becomes even more important, as a missing component can shut down the entire assembly line, and there are no vehicles ‘in stock’.

This speed means that consolidation of components for shipping is much less possible. Agility and reliability are key, with the trend towards near-shoring suppliers in order to cut lead-times even further.

Aftermarket agility

It’s not just inbound logistics that is facing upheaval. Aftermarket supply chains are also being re-imagined. With the significantly lower number of parts and components, added to the lower likelihood of them needing to be replaced, the focus is on accessories. The expectation of today’s customers is that accessories are available for purchase immediately, either in the show room or online. This requires an approach more akin to consumer lifestyle logistics than traditional automotive, an area we at Kuehne+Nagel are also experts in.

When components of BEV and HFC vehicles do fail or need to be replaced for whatever reason, the absence of a traditional dealer network means that the mobile mechanic will visit the customer either at their place of work or at home. This also means that without the capacity to stock parts and components, the rapid, just in time delivery of the required item becomes vital to ensure the vehicle is back on the road as quickly as possible.

Not only are we helping our customers transition to new generation vehicles to ensure a sustainable future, but we’ve made a true commitment to net zero carbon ourselves with a huge investment in digital supply chain solutions. We also plan to achieve carbon neutrality for our suppliers’ and customers’ footprint by end 2030.

Experience counts

At Kuehne+Nagel we’ve been working with our automotive customers, both established and new, for some time now to anticipate future needs and design their supply chains to respond to these new market realities.

Contact our automotive experts to see how Kuehne+Nagel can help you re-imagine your supply chains.